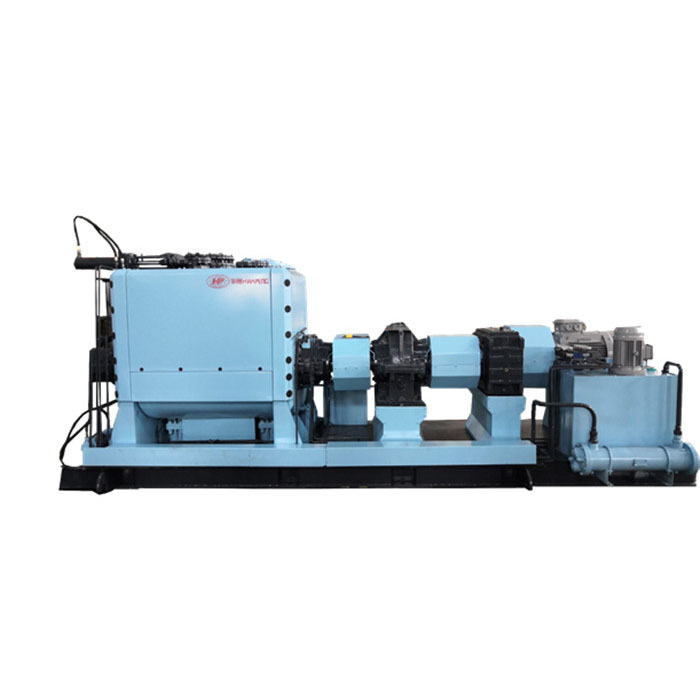

HP-H(H)KC Yakanyanya Kushanda Preheating Preheating Kneading Cooling System yeSpecial Graphite

HP-H(H)KC Series Yakakwira Inoshanda Preheating Kneading Cooling System inonyanya kushandiswa mukugadzirira paste muindasitiri kabhoni, kugadzira prebaked anode, aluminium cathode, graphite electrode, yakakosha graphite uye zvimwe zvigadzirwa.Mushure mekunge muunganidzwa wadziiswa kune yakatarwa tembiricha yemuchina wekupisa, inopinda mumushini wekukanya kuti ipedze kukanya zvinhu zvakaoma uye binder pitch, ichigadzira paste ine yakanaka plasticity, uye paste inopinda mumushini wekutonhora kuti utonhodze. iyo yakatarwa yekuumba tembiricha.

HP-H (H) KC Yakakwira Inoshanda Preheating Kneading Cooling System ine nyowani inoshanda-yepamusoro-tembiricha tank, yakakwirira-inoshanda yakakwirira-yekushisa yekusanganisa blade, chengetedzo yekutarisa sisitimu inotenderera inotenderera, nyowani yekuvharisa chisimbiso chekusanganisa blade shaft kupera, kuchengetedza kuchengetedza. mudziyo wekusanganisa blade, chaiyo-nguva yekutarisa sisitimu yekusanganisa blade, pitch yunifomu yekudyisa mudziyo, yekufambisa sisitimu ine simba rekutakura uye kushanda kwakavimbika, kutsiva kuri nyore kweplate yemwenje, tembiricha yekuyeresa tembiricha, nezvimwe, kuve nechokwadi kuti kushanda kwemidziyo kunoshanda. , yakagadzikana uye yakavimbika.

Kuita kwehunyanzvi

Mushure mekurapa kwepamusoro, kushata kwepamusoro kwechikamu chakakomberedzwa uye pamusoro peiyo blade yekusanganisa inosvika 0.1, kusanganisa uye kutonhora zvinhu zvinosiyana, hazvisi nyore kunamatira kune yekusanganisa blade, uye hupenyu hwesevhisi hwekusanganisa blade makore makumi maviri.

Inotora tekinoroji nyowani yakawedzera-inoshanda tangi tekinoroji, yakakwirira-yepamusoro-tembiricha tangi patent tekinoroji, kusanganisa blade yekudziya patent tekinoroji, nyowani yekusanganisa blade yekudziya patent tekinoroji uye yakazara-nzvimbo yekudziya tekinoroji.Iyo yakaoma zvinhu ine kukurumidza kupisa kukurumidza uye yakanyanya kupisa kunyatsoshanda.

Iyo yakaoma yekusanganisa preheating chikamu inotora tangent, kukurumidza kwakasiyana uye radius yakaoma zvinhu musanganiswa uye tekinoroji yekudziya kusanganisa zvinhu zvakaenzana.

Kukanyira kwepaste kunotora inopindirana synchronous kusanganisa blade, pamusoro pekusanganisa tekinoroji.Zvishandiso zvinokanywa zvakaenzana pasina kukanya bofu angle uye block raw material.

Akashongedzerwa nemuunganidzi weguruva kuti aunganidze guruva rakaburitswa panguva yakaoma yekudyisa musanganiswa wakaoma uye kuchengetedza zvakatipoteredza.Iyo huruva yakaunganidzwa ichadzoka yega uye inoramba ichitora chikamu mukuoma kusanganisa maitiro kuti ive nechokwadi chekuenzanisa kwezvinhu uye kunaka kwechigadzirwa.

Iyo tekinoroji ine patent yemusangano mutsva wekuyera tembiricha yekuyera inogamuchirwa, iine kuyerwa kwetembiricha chaiyo uye kukanganisa kuyerwa kwekushisa kwe ± 2 ℃.

Iyo tekinoroji yakasanganiswa inoputirana simbi mhete chisimbiso tekinoroji inogamuchirwa kuti ive nechokwadi chekuti hapana kabhoni poda kuvuza pamagumo eshaft yeblade yekusanganisa.

Iyo tangi yakagadzirwa nechepasi-alloy yakakwirira-simba simbi ndiro Q460D.Iyo yemukati pamusoro petangi inobatwa nehupamhi hwepamusoro hwe 0.1.Izvo zvinhu hazvisi nyore kunamatira kune tangi.Hupenyu hwesevhisi yetangi makore makumi maviri.

Kupfeka kusagadzika welding layer yakafukidzwa pamusoro peiyo yekusanganisa blade, uye hupenyu hwesevhisi hwemusanganiswa blade makore makumi maviri.

The unloading system inoshandisa hydraulic turnover kukiya gedhi rekuburutsa kuti ive nechokwadi chekuti hapana chabuda.Tangi negedhi rekuburitsa hazvizoderere kabhoni poda.

Iyo yekusanganisa blade inotakura yakagadzirirwa kufambiswa kudzivirira blade yekusanganisa kubva pakupisa, kuwedzeredzwa nekunamira; Iyo yekusanganisa blade inoshongedzerwa ne-bi-directional thrust bearing kudzivirira blade yekusanganisa kubva pakukuya tangi.

Iyo tangi ine chimiro chakasiyana, uye chiteshi chekudyisa uye guruva rekuunganidza chiteshi zvakachengetwa pachivharo chepamusoro.

Yakashongedzerwa neiyo chaiyo-nguva yekutarisa sisitimu yekudziya huru yeinjini huru, alarm nekukurumidza kana paine abnormality.Iyo shaft huru inotakura kutonhora uye yekutarisa system yakashongedzerwa kutonhodza main shaft inotakura munguva chaiyo, tarisa kutonhora kwepakati tembiricha, kuyerera uye. mamwe ma parameter munguva chaiyo, uye kupa aramu pakarepo kana pane abnormality.Iva nechokwadi chekuchengetedzwa kwakachengeteka, kwakavimbika uye kwakagadzikana kushanda kwepindle-bearing system munzvimbo yakakwirira yekushisa.

Yakashongedzerwa nekusanganisa blades kuchengetedza mudziyo wekudzivirira. Cheka simba nekukurumidza kudzivirira kusanganisa blade kubva mukukuvadzwa kana yakawandisa.Mushure mekunge mutoro wadzokera kune zvakajairika, tanga zvakananga mota huru, mudziyo wekuchengetedza kuchengetedza unosanganisa uye unodzosera simba, uye sisitimu inodzokera kune yakajairika kushanda.

Technical Parameters

| Special graphite yakaoma zvinhu preheating muchina | HP-DMH(H)600-SG | HP-DMH(H)2000-SG | HP-DMH(H)3000-SG |

| Yakatemerwa Vhoriyamu (L) | 600 | 2000 | 3000 |

| Mhepo yakakura kwazvo (L) | 1150 | 3680 | 3900 |

| Revolution yeKusanganisa Blade (RPM) | 16/13 | 12/15 | 12/15 |

| Heating Method | Kupisa mafuta ekufambisa | Kupisa mafuta ekufambisa | Kupisa mafuta ekufambisa |

| Working Pressure (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |

| Kneading Method | Tangent yakasiyana velocity radius | Yakasiyana tangent radius | Tangent yakasiyana velocity radius |

| Special Graphite Kneader | HP-CPK600-SG | HP-CPK2000-SG | HP-CPK3000-SG |

| Yakatemerwa Vhoriyamu (L) | 600 | 2000 | 3000 |

| Mhepo yakakura kwazvo (L) | 1000 | 3450 | 4800 |

| Kneading Method | Mharadzano yakafanana velocity superradius | Mharadzano yakafanana velocity superradius | Mharadzano yakafanana velocity superradius |

| Revolution yeKusanganisa Blade (RPM) | 16 ~ 32 (inochinjika) | 16 ~ 32 (inochinjika) | 12 ~ 18 (inochinjika) |

| Heating Method | Kupisa mafuta ekufambisa | Kupisa mafuta ekufambisa | Kupisa mafuta ekufambisa |

| Working Pressure (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |

| Special Graphite Paste Kneading Cooler | HP-PKC600-SG | HP-PKC2000-SG | HP-PKC3000-SG |

| Yakatemerwa Vhoriyamu (L) | 600 | 2000 | 3000 |

| Mhepo yakakura kwazvo (L) | 1000 | 3850 | 5200 |

| Revolution yeKusanganisa Blade (RPM) | 5 ~ 10 (inochinjika) | 5 ~ 10 (inochinjika) | 5 ~ 10 (inochinjika) |

| Mixing Method | Mharadzano yakafanana velocity superradius | Mharadzano yakafanana velocity superradius | Mharadzano yakafanana velocity superradius |

| Kutonhodza Nzira | mvura inotonhorera | mvura inotonhorera | mvura inotonhorera |

| Working Pressure (MPA) | 0.3 | 0.3-0.4 | 0.3-0.4 |