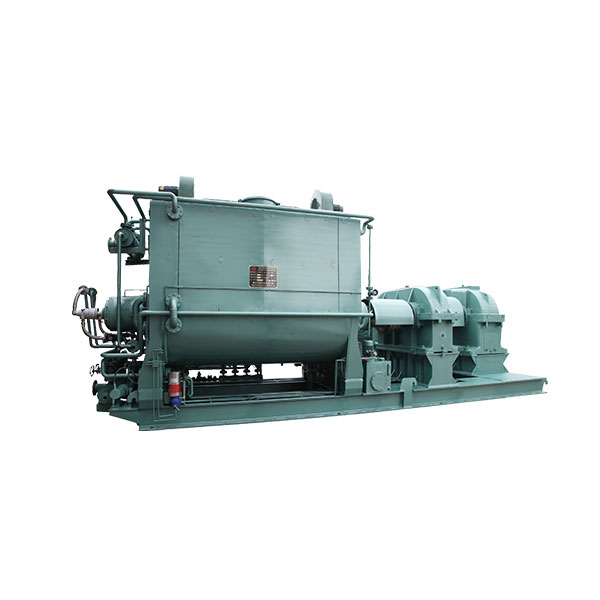

HP-H(H)KC Series Yakakwirira Inoshanda Preheating Kukanyira Kutonhorera System

HP-H(H)KC Series Yakakwira Inoshanda Preheating Kneading Cooling System inonyanya kushandiswa mukugadzirira paste muindasitiri kabhoni, kugadzira prebaked anode, aluminium cathode, graphite electrode, yakakosha graphite uye zvimwe zvigadzirwa. Mushure mekunge muunganidzwa wadziyirwa kune yakatarwa tembiricha mumuchina wekupisa, inopinda mumushini wekukanya kuti upedze kukanya zvinhu zvakaoma uye binder pitch, ichigadzira paste nepurasitiki yakanaka, uye paste inopinda mumushini wekutonhora kuti utonhodze. iyo yakatarwa yekuumba tembiricha.

HP-H (H) KC Yakakwira Inoshanda Preheating Kneading Cooling System ine nyowani inoshanda-yepamusoro-tembiricha tangi, yakakwirira-inoshanda yakakwirira-yekushisa yekusanganisa blade, chengetedzo yekutarisa sisitimu inotenderera inotenderera, nyowani yekuvharisa chisimbiso chekusanganisa blade shaft kupera, kuchengetedza kuchengetedza. mudziyo wekusanganisa blade, chaiyo-nguva yekutarisa sisitimu yekuvhenganisa blade, pitch yunifomu yekudyisa mudziyo, transmission system ine yakasimba kutakura uye yakavimbika. kushanda, kutsiva kwakaringana kweplate yekubikira, tembiricha yekuyeresa tembiricha, nezvimwe, kuve nechokwadi chekuti mashandiro emidziyo inoshanda, yakagadzikana uye yakavimbika.

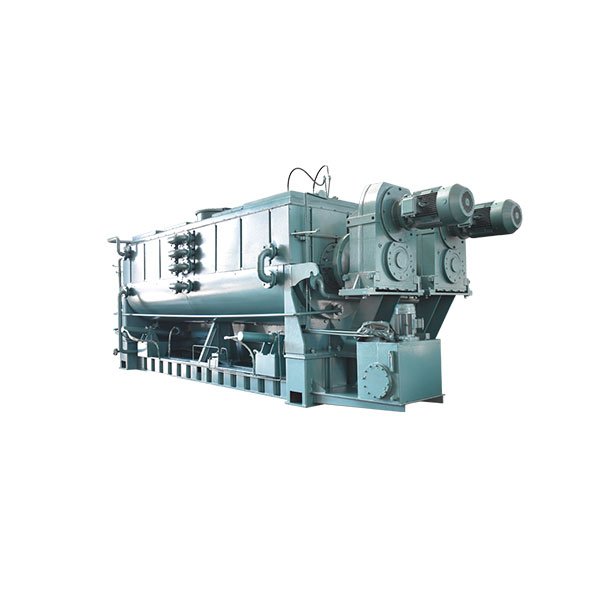

HP-DMH SERIES

DRY MATERIAL PREHEATER

Matekinoroji ekusimbisa-kupisa akawanda anogamuchirwa, zvinhu zvakaoma zvinogona kupiswa kusvika 180 ℃ mu30min kana HTM iri 260 ℃.

Kushanda Kwehunyanzvi

1. High preheating quality

Inotora tangent uye mutsauko wekusanganisa blade yakaoma zvinhu kusanganisa uye tekinoroji yekudziya, izvo zvinhu zvinogara zvichibata kupisa kwekutapurirana pamusoro pemidziyo zvakananga kuona kusanganisa uye kupisa.

2.Fast kupisa kutengesa uye kupisa kwakanyanya

Gamuchira tekinoroji yakakwira tembiricha patent tekinoroji (yekutanga patent nhamba: ZL201210124643.8), mhando nyowani yekusanganisa blade patent tekinoroji (Patent Nhamba: ZL 201610897074.9, ZL201610897263.6), yakazara yekupisa patent nhamba (yekugadzira patent tekinoroji ZL200420018996.0), kusanganisa blade kudziyisa patent tekinoroji (nhamba yepatent: ZL200620085174.3), kuburitsa gedhi rekudziya tekinoroji lining plate uye tank isina musono yekukodzera tekinoroji.

3. Guarantee yakaoma zvinhu particle saizi chikamu

Shandisa yakakosha michina kugadzirisa mukati medhayamita yetangi uye gomba rinotakura retangi yekupedzisira ndiro, iyo yakakwira machining inovimbisa gap chinodiwa pakati pekusanganisa blade netangi uye inodzivirira zvimedu kubva pakukuya panguva yekusanganiswa nekudziya.

4. Kuyera kuyera kwakarurama

Gamuchira tekinoroji yekuyera tembiricha (patent Nha.: ZL201420490132.2) kuvandudza tembiricha yekuyera kuita kwe thermo-inopindura uye inopesana nekupindira.

5. Yakakwana mhepo yakasungwa

Adopt yakasanganiswa inoputika mhete yesimbi kuti iumbe chisimbiso chakawanda (nhamba yepatent: ZL 2014 2 0490187.3) kuvimbisa kuti hapana kabhoni poda inodonha kubva kumucheto weshaft yekusanganisa blade; Hydraulic rotary lock discharge gedhi ine yakanakisa kusimba kwemhepo, yekuisa chisimbiso iyo isingafe yakasakara kuti kusimba kwemhepo kwakavimbika pasina kubuda kwezvinhu kubva kugedhi rekuburitsa.

6. Kukurumidza kubuda, hapana zvinhu zvakasara

Kusanganisa mablades kusundira zvinhu spiral kuti zvipere nekukurumidza. Material anoburitswa kunze zvachose kubva pazasi discharge gedhi mune isingasviki 2min pasina chasara.

7. Hapana kubuda kwehupfu panguva yekubvisa zvinhu

Kuisa chisimbiso hopper seals discharge door zvachose, hapana poda inoburitswa panguva yekubuda kwezvinhu. Yese ma hydraulic Executive maitirwo emusuwo wekuburitsa akaiswa kunze kwekuvharisa hopper kuti itarise nyore uye kugadzirisa.

8. High kupfeka-resistance lining plate

Kusanganisa blade kwakaiswa pamusoro-welded neakapfeka-resistant layers, kuomarara kwayo kunosvika HRC665, uye hupenyu hwesevhisi hwekusanganisa blade makore makumi maviri. Rudzi rutsva runopfeka-resistant manganese simbi zvinhu zvinoshandiswa semarata ekumisa ane simba rakawanda mushure mekupisa kwekupisa. Upenyu hwebasa remarata ekugadzira anode makore gumi nemashanu uye gore 1 ndeyekugadzira cathode uye kabhoni electrode.

9. Kusanganisa blade chimiro chakakodzera kune yakakwira tembiricha yekushanda nharaunda

Kutakura kunofamba kana kusanganisa blade kunorebesa pasi pekupisa kudzivirira kutakura kuvharika kunokonzerwa nekusanganisa blade kutambanudza kwenguva refu. Bearing chamber ine inotonhorera chimiro inovimbisa yakajairika tembiricha yebasa uye inowedzera hupenyu hwesevhisi yekubereka Bearing chamber ine inotonhorera bhachi remvura kuvimbisa tembiricha yekushanda pasi pekushisa kwakanyanya uye kuwedzera hupenyu hwayo hwesevhisi. Kusanganisa mablades anomhanya kazhinji pasi pekupisa kwakanyanya.

10. Kuvimbika kushanda kwehurongwa hwekutumira

Transmission system inoumbwa nemaster mota, P yakatevedzana yakaoma mazino ekudzikisa giya, inotakura huwandu hwayo hunosvika katatu iyo yeakajairika mazino ekudzikisa giya, kuti midziyo irege kukuvadzwa kana zvinhu zvakaoma zvekunze zvinowira mukati metangi uye kuvhara mashizha ekusanganisa. .

11. Mutsindo wakaderera

Iyo inogadzirwa nemichina yakakosha, ine yakanaka concentricity, kushanda kwakatsetseka, hupenyu hwesevhisi hurefu, uye ruzha rwekushandisa rwemuchina wese hausi pasi pe80dB.

12.PLC yakazara otomatiki kudzora

PLC kutonga uye internet kutaurirana inogamuchirwa kuyera kuratidza uye kutumira michina inomhanya uye mamiriro maparamendi panguva chaiyo (inosarudzika kumisikidzwa). Matatu emhando dzekushandisa modhi - internet otomatiki, imwe muchina otomatiki uye manejimendi - vimbisa kuti muchina pachawo unogona kumhanya wega zvisinei kana kumusoro uye kuzasi michina iri otomatiki.

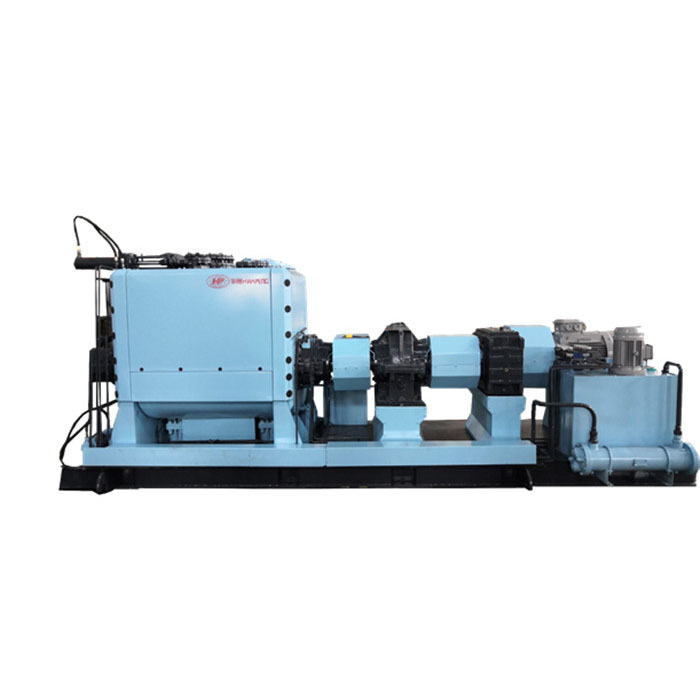

HP-CPK SERIES

CARBON PASTE KNEADER

HP-CPK Series Carbon Paste Kneader (yekutanga patent nhamba: ZL20141 0430160.X,ZL201420490132.2) inotora akati wandei ematekinoroji ematekinoroji, ayo anovimbisa kunaka kwakanakisa kwekukanyira, kushanda kwechisimbiso kwakanakisa pasina guruva uye hutsi hunobuda.

Kushanda Kwehunyanzvi

1. High mixing quality

Iyo inotora inopindirana, inopindirana yekusanganisa blade tekinoroji kubva kuJapan. Kusanganisa mablades radius inodarika yepakati petangi iyo inosimudzira actuating nzvimbo; mashizha maviri ekusanganisa ane denderedzwa rakafanana rekukwira asi rakasiyana rinotenderera, rimwe blade rekusanganisa rinosunda zvinhu kusvika pakati uye rimwe rinosundira kumativi ose, zvinhu zvinoyerera se "8" mutangi.

Chikamu chebadza chinonzi elliptic chinosundidzira zvinhu kuti zvifambe pamwe chete negwara rakamira rechikamu cheelliptic, kudzvanya chiito kunowedzera, zvinhu zvimedu zvinosanganiswa zvakakwana, kusanganisa uye kukanya maitiro kunosimbiswa. yekusanganisa mablades haina zvinhu.

2.Fast kupisa kutengesa uye kupisa kwakanyanya

Gamuchira tekinoroji yepamusoro yekupisa tangi patent tekinoroji (yekutanga patent nhamba: ZL 2012 1 0124643.8) (iyi yakagadziridzwa gadziriso), yakazara yekupisa patent tekinoroji (yakagadzirwa patent nhamba: ZL2004 2 0018996.0), kusanganisa blade kupisa patent tekinoroji (yakagadzirwa patent nhamba2006 2 0085174.3) (iyi yakagadziridzwa kumisikidzwa), discharge gedhi rekudziya tekinoroji, lining plate uye tank seamless yekubatanidza tekinoroji.

3. Guarantee yakaoma zvinhu particle size Proportion

Shandisa midziyo yakakosha kugadzirisa mukati medhayamita yetangi uye gomba rinotakura retangi yekupedzisira ndiro, machining echokwadi akakwira uye inovimbisa gap rinodiwa pakati pekusanganisa blade uye tangi kudzivirira zvimedu kubva pakukuya panguva yakaoma musanganiswa uye kupisa.

4. Pitch kugovera yunifomu

Pitch kugovera mudziyo wakaiswa pabutiro kuti uwedzere namo mutangi zvakafanana kuburikidza neakawanda mapoinzi, kuiswa kweyakaoma zvinhu block munamira kunodziviswa.Mudziyo unodziiswa nemafuta ekutepfenyura kuti udzivise gomo rinovharira mudziyo.

5.Temperature kuyerwa kwakarurama

Gamuchira tekinoroji yekuyeresa tembiricha (patent Nha.:Z2014 2 0490132.2) kuvandudza tembiricha yekuyera kuita kwe thermo-inopindura uye anti-kupindira.

6. Yakakwana mhepo yakasungwa

Adopt yakasanganiswa inoputira mhete yesimbi kuti igadzire kuvharika kwakawanda (nhamba yepatent: ZL 2014 2 0490187.3) kuvimbisa kuti hapana kabhoni poda inodonha kubva kumucheto weshaft yekusanganisa blade; Hydraulic rotary lock discharge gedhi ine yakanakisa kusimba kwemhepo, yekuisa chisimbiso iyo isingasakara kuitira kuti kusimba kwemhepo kuve kwakavimbika uye hakuna zvinhu zvinobuda kubva pagedhi rekuburitsa.

7. Kukurumidza kubuda, hapana zvinhu zvakasara

Kusanganisa blades kusunda zvinhu spiral uye zvinhu zvinoraswa nekukurumidza. Gedhi rekuburitsa riri pazasi petangi, zvinhu zvinoburitswa kunze zvachose pasina zvakasara, nguva yekubvisa zvinhu isingasviki 2min, uye hapana chakasara mutangi.

8. High kupfeka-resistance

Kusanganisa blade yakashongedzerwa nepamusoro-soro nemachira-asingachinjiki ane kuomarara kusvika kuHRC6065, uye hupenyu hwesevhisi hwekusanganisa blade makore makumi maviri. Tangi lining mahwendefa anoshandisa mhando nyowani kupfeka-inodzivirira manganese simbi zvinhu zvine simba rakanakisa mushure mekupisa kwekupisa. Upenyu hwebasa remarata ekugadzira anode imakore gumi nemashanu uye igore rimwe kugadzira cathode uye kabhoni electrodes.

9.Bearing chimiro chekusanganisa blade chakavimbika

Kusanganisa blade shaft inotora yega-inogadzika roller kutakura uye kaviri-direction thrust kutakura dhizaini iyo inokunda axial simba rekusanganisa blade uye inodzivirira kusanganisa maredhi kubva kuaxial kushanduka uye hupenyu hwesevhisi hwekubereka hwakareba. Chimiro chekutakura chinomisikidzwa kune rumwe rutivi uye chinofambiswa kune rumwe rutivi, izvo zvinobvisa pesvedzero yekuwedzera kwekupisa uye kudzivirira kusanganisa blade kubva pakubata mushure mekupisa nemafuta ekupisa.

10.Kutendeseka kushanda kwemaitiro ekutumira

Iyo inotora mazino akaoma ekudzikisa giya bhokisi uye synchronous giya bhokisi rakakamurwa chimiro nekuzara kuzere uye kushanda kwakavimbika. Mazino akaoma ekudzikisa giya, inotakura huwandu hwayo 3 nguva dzeyakajairwa, pamwe nekubatanidza giya, inovimbisa yakakwirira kutakura yekutakura system. Hydraulic clutch inogona kugadzirisa transmitted torque zvinoenderana nemutoro kuti upe kudzivirira kwekuremerwa, uye bvumidza muchina kuti utangezve nemutoro kana paine akakosha mamiriro (sekutangazve mushure mekumira panguva yekumhanya).

11. Mutsindo wakaderera

Iyo inogadzirwa nemidziyo yakakosha kuwana yakanaka concentricity, ichiita kuti oparesheni ipfave, hupenyu hwesevhisi hurefu, uye ruzha rwekushanda kwemuchina wese pasi pe80dB.

12. PLC yakazara otomatiki kutonga

PLC kutonga uye kutaurirana kweinternet kunogamuchirwa kuyera, kuratidza uye kufambisa michina inomhanya uye mamiriro maparamendi panguva chaiyo (sarudzo yekumisikidza). Mhando nhatu dzekushandisa mode internet otomatiki, muchina mumwe otomatiki uye manyorero - vimbisa kuti muchina wacho pachawo unogona kumhanya wega zvisinei kana mashini ekumusoro nekudzika ari otomatiki.

HP-PKC SERIES

CARBON PASTE KNEADERING COOLER

HP-PKC yakatevedzana paste yekukanya inotonhorera (Invention Patent No 20121099062.3) inotungamira pasi rose kukanya muchina.Inotora tekinoroji yekukanyisa tekinoroji inokanyiwa zvakare apo kutonhora, kukanya kunaka kunovandudzwa.Namira mushure mekutonhodza s inopararira neatchlomeration, uye pie inoregedzwa zvachose, uye inosvika padanho repasi rose rezvigadzirwa zvakafanana.

Kushanda Kwehunyanzvi

1.Kupisa kwakadzika kusanganisa uye kutonhora

Adopt kabhoni paste inotonhorera tekinoroji (Invention Patent NO.: ZL 2012 1 0099062.3), namira inotonhorera tekinoroji (patent Nhamba: ZL 2009 2 0273347.8) kukanya pasi petembiricha yakaderera uchitonhodza kabhoni paste. Mushure mekuti kabhoni paste yakakandwa uye yatonhodzerwa kusvika 130 ℃ (tembiricha yakadaro ine hukama nemhando yepitch), nekudzikira kwetembiricha, kuumbwa kwepitch adsorption layer paaggregate surface kunowedzera kushanda, uye iyo yakaturikidzana chimiro chepitch adsorption layer. kunowanzo kurongeka zvakarongeka, izvo zvinobatsira kuvandudza conductivity yezvigadzirwa zvekabhoni.

2. Molding volume density inovandudzwa ne0.02

Carbon chigadzirwa kuumba uye kupedzwa chigadzirwa vhoriyamu density inovandudzwa ne0.02 pasi peiyo yakafanana yekuumba mamiriro.

3. Goho rinovandudzwa ne2-5%

Kabhoni chigadzirwa chakaremara chinobviswa, goho rechigadzirwa chakapedzwa chakagadzirwa neyakatonhorera kabhoni paste chinovandudzwa ne2-5% pasi pemamiriro akafanana ekuita.

4. Kuwanda kwenzwi kunoderedzwa ne2%

Pitch yekushandisa huwandu mune yakapfuura "kusanganisa" maitiro ekugadzira inoderedzwa neinopfuura 2%.

5. Yakatonhodzwa paste iri incompact

Iyo kabhoni paste inotonhorera tekinoroji inogamuchirwa iyo yakakosha yakagadzirirwa kusanganisa blades kusanganisa uye kuparadzira paste zvine simba.

6. Yakatonhodzwa kabhoni paste ndeye tembiricha yakafanana

Carbon paste inosanganiswa uye yakatonhodzwa pasi nekutenderera kutonhora svikiro panguva imwe chete. Mashizha maviri ekusanganisa anotenderera achienderana asi akatarisana, saka zvinhu zvinoyerera zvakarongeka mutangi, izvo homogenize tembiricha yekunamira uye midziyo, kuderedza kusanganisa kuramba uye kuchengetedza midziyo yekutyaira simba.

7.Cooling kunyatsoshanda kwakakwirira

Adopt kusanganisa blade kudziyisa tekinoroji (patent Nhamba: ZL 2006 20085174.3, blade yekusanganisa ine inotonhorera mukati kuti itonhodze pasi paste), nzvimbo yese yekudziya tekinoroji (patent No.. ZL20042 0018996.0), yakadzika kupisa kupisa bhachi, zvinhu zvinoburitsa gedhi kutonhora uye lining ndiro uye tangi seam- isina-kukodzera uye imwe yekutonhodza-inosimbisa tekinoroji.

8. Hutsi hunobuda zvachose

Iwo akanyatso gadzirwa mablades anoparadzira paste nguva nenguva kuti iite kutiza kupukunyuka kwehutsi hunokachidzirwa.

9.Temperature kuyerwa kwakarurama

Gamuchira tekinoroji yekuyeresa tembiricha (patent No. ZL2014 2 0490132.2) kuvandudza tembiricha yekuyera kuita kwe thermo-inopindura uye inopesana nekupindira.

10. Kukurumidza kubudiswa kwezvinhu, hapana zvinhu zvakasara

Kusanganisa blade kunosundidzira zvinhu spirally kuburitsa zvinhu nekukurumidza uye zvizere kubva pasi rakavhurika gedhi rekuburitsa mukati isingasviki 2 min pasina chasara.

11. High kupfeka resistance

Kusanganisa blade kwakaiswa pamusoro-welded neakapfeka-resistant layers, kuomarara kwayo kunosvika HR6065, uye hupenyu hwesevhisi hwekusanganisa blade makore makumi maviri. Rudzi rutsva runopfeka-resistant manganese simbi zvinhu zvinoshandiswa se lining pate ine simba rakawanda mushure mekupisa kwekupisa. Upenyu hwebasa remarata ekugadzira anode s15 makore uye 1 gore ndeye cathode uye kabhoni electrode kugadzirwa.

12. Kutakura chimiro chekusanganisa blade chakavimbika

Kusanganisa blade shaft kunotora yega-inogadzirisa roller kutakura uye kaviri-direction thrust kutakura dhizaini iyo inokunda axial simba rekusanganisa blade uye inodzivirira kusanganisa mablade kubva kuaxial kushanduka uye hupenyu hwesevhisi hwekubereka hwakareba. Chimiro chekutakura chinomisikidzwa kune rumwe rutivi uye chinofambiswa kune rumwe rutivi, izvo zvinobvisa pesvedzero yekuwedzera kwekupisa uye kudzivirira kusanganisa blade kubva pakubata mushure mekupisa nemafuta ekupisa.

13. Kushanda kwakavimbika

Iyo inotora mazino akaoma ekudzikisa giya bhokisi uye synchronous giya- bhokisi rakakamurwa chimiro nekuzara kwakazara uye kushanda kwakavimbika. Mazino akaoma ekudzikisa giya, inotakura huwandu hwayo 3 nguva dzeyakajairwa, pamwe nekubatanidza giya, inovimbisa yakakwirira kutakura yekutakura system. Hydraulic clutch inogona kugadzirisa transmitted torque zvinoenderana nemutoro kuti upe kudzivirirwa kwekuremerwa, uye bvumidza muchina kuti utangezve nemutoro kana paine mamwe mamiriro akakosha (sekutangazve mushure mekumira panguva yekumhanya)

14. Mutsindo wakaderera

Iyo inogadzirwa nemichina yakakosha, kuwana yakanaka concentricity, kuita kuti oparesheni ipfave, hupenyu hwesevhisi hurefu, uye ruzha rwekushanda kwemuchina wese pasi pe80dB.

15. PLC yakazara otomatiki kutonga

PLC kutonga uye kutaurirana kweinternet kunogamuchirwa kuyera, kuratidza uye kuendesa michina inomhanya uye mamiriro maparamendi panguva chaiyo (sarudzo yekumisikidza). Mhando nhatu dzemashandisirwo emhando ---internet otomatiki, muchina mumwe otomatiki uye manyorero.